Chain Disk

Chain Disk delivery systems have the flexibility to adapt to all types of brewing and distilling facilities and the ability to overcome the performance and reliability constraints of other conveyor systems. The gentle conveying method limits damage to your malt and keeps your grist profile and efficiency consistent. Chain Disk's rugged design, quality components and unique control system enable it to outperform the competition in capacity, distance, durability, and price.

Available in 2.375" or 4" diameter sizes, stainless steel upon request, and a variety of other special add-ons, this type of chain and puck conveyor provides high quality performance at a great value.

Flex Auger

One of the most affordable ways to move your grain, flex augers are a great option for simple routes, particulary pre-mill. Using PVC tubing as the carrier of your grain not only provides some amount of flexibility in placement, but reduces dust, provides protection against insect and rodent contamination, and reduces noise. Available in 2.2" on up to 5" diameters, flex augers can meet the needs of almost any size production. We also offer other auger options including galvanized tubing and rigid augers.

Bucket Elevators

An extremely reliable, gentle, and maintenance-free conveyance for moving grain vertically, bucket elevators can be a great solution for any size facility. Particularly useful for certain types of outdoor silo filling, extra-delicate material handling, or compact lateral spaces.

Spent Grain Removal

Sick of dealing with all those barrels of spent grain by hand? Creating a system to handle your spent grain is just as important as one for your dry malt. Sometimes an afterthought until reaching a certain size, even a smaller startup operation can have issues dealing with spent grain that we can help solve in an affordable way.

Add flexibility and economy in your scheduling to have your spent grain taken away. Conveyance lines, pumps, and storage bins for spent grain are all options that we can customize to your setup to increase productivity, reduce labor and even improve sanitation for your employees.

An elevated spent grain bin with a drive-thru support structure will simplify the disposal of your brewery spent grain, making it easy to offload into whatever type of trailer will be used to haul it away. A spent grain bin can also help delay the mold & bacterial growth often associated with spent grain storage, reducing foul odors that can upset the neighbors. Your spent grain bin can be equipped with heating and insulation, mild powder coated or stainless steel, and either on a raised structure or ground mounted with pump out. Bins on raised structures can be fitted with discharge screws or gravity drop chute. Add any of these combinations to help keep things clean and facilitate off-loading.

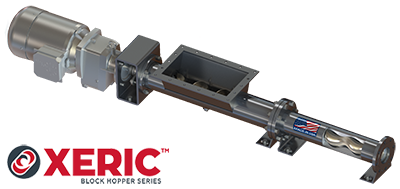

Progressive Gravity Pumps

We can source any type of pump desired, but the main type of pump we use in our systems are progressive cavity pumps, or positive displacement pumps. Reliably efficient, dry-run capable, and with a compact design, the Xeric Black Hopper Series from Roper Pumps offers gentle and stable conveyance with economical operation.

Connect directly to a mash/lauter discharge, or connect to custom-made hopper positioned next to a manway door and you can save thousands in labor and avoid unnecessary down time with a progressive cavity spent grain pump. Not only will it save you money, it will save your back!

Silo Discharge Screws

When you want a long-lasting, high-throughput way to discharge your spent grain bin and gravity dropping isn't possible, a discharge or dosing screw is a great option to work with almost any consistency of spent grain. Built in robust stainless steel, and available with heat tracing and automatic valves.

Centrifuges and Separation

The use of separators in different brewery applications goes back to the beginning of the 1900s. Based on long-term collaboration with the brewery industry, Alfa Laval separators are specially designed for the requirements and demands of this industry.

Brewery separators are high performance clarifiers with intermittent solids discharges. The design ensures low power consumption and keeps the oxygen pick-up at a minimum.

Malt Handling also offers centrifuge decanters for the distilling industry. A decanter will help get more solids out of your slurry, allowing you to safely dispose of or recirculate water, and reduce your total spent grain cake volume.

Dust Collection

While it is always a good idea for any grain handling operation to be equipped with some form of daily maintenance and dust control, some situations will actually require it. More and more, inspectors and fire marshalls are erring on the side of caution and making brewers and distillers outfit their milling operations with specialized motors, electrical, and ventilation.

Malt Handling offers dust collection equipment for any type of hazardous location. Built in accordance with NFPA and NEC requirements for hazardous conditions and ideal for use inside Class I, Group D and Class II, Groups F & G rated atmospheres, we can provide dust collection units that are capable of safely removing large quantities of combustible dusts and particles.

From outdoor bag houses with ducted collection points to rolling portable vacuum units, we have options for just about any requirements. In addition, almost all of our grain handling equipment is available with explosion-proof motors or enclosures safe for their environment.

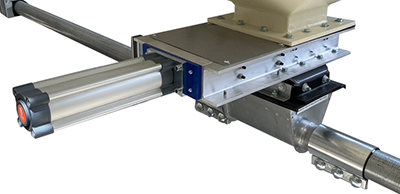

Knife Gate Valves

For handling and controlling dry or spent grain in a reliable, efficient manner. Malt Handling sells high quality knife gates that are key for accurate weighing and batching processes, cutting off flow of material to conveyor or grain receptacle. Available for both dry and wet applications, with options for proximity sensors for open/shut signalling and positioners to control output.

Automation and Integration

Let us simplify the brewing process by automating your malt handling equipment. Our automated control panel connects all the moving pieces of your brewery or distillery into one digital touchscreen. From the dry grain bin to mill to spent grain controls, we can automate the weighing, milling, and batching of your ingredients to your exact specifications. Developing consistency in your brewing process helps maximize extraction efficiencies and reduce labor costs. so investing in high-quality automation is almost always worthwhile.

Full scale automation too much for your needs? No problem, we also make more basic controls, from simple start-stop switches to multi-switch control panels. Get in touch with us below to have a conversation about setting up the right system for you.